3 Step Wet Diamond Polishing Pad for Stone

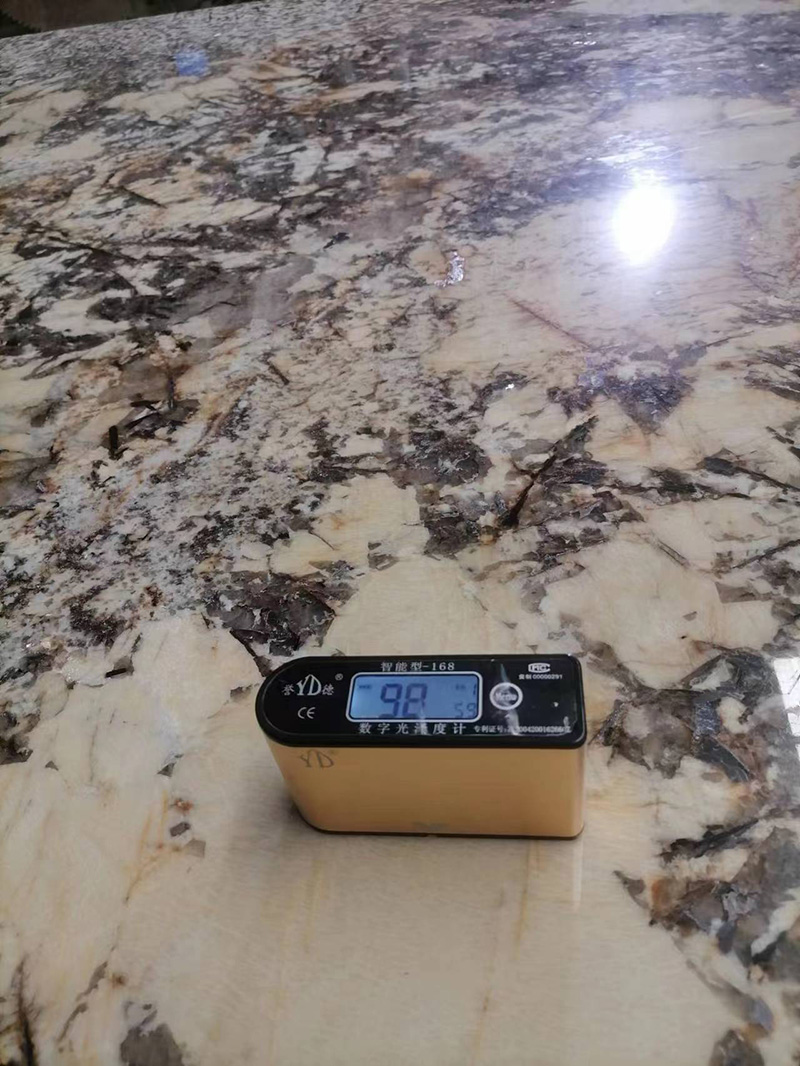

3 step wet Diamond wet polishing pad is designed for polishing on granite, marble, concrete and other stones surface. Saves four steps compared with the traditional wet diamond polishing pad, which greatly improves the grinding efficiency. The product is popular in foreign countries, it means the top quality with competitive price in the market.

3 step wet Diamond wet polishing pads are specially formulated with high-quality diamond particles embedded in resin matrix, providing excellent cutting and polishing performance. The 3-step wet diamond polishing pads are designed to be used with water, the water acts as a lubricant to reduce friction and prevent overheating. This wet polishing method ensures a cleaner working environment and produces superior polishing results.

The3 Step Wet Diamond Polishing Pad is an exceptional tool designed specifically for the polishing of granite, marble, concrete, and other stone surfaces. Renowned for its superior performance and time-saving capabilities, this innovative pad is revolutionizing the industry by streamlining the polishing process.

Compared to traditional wet diamond polishing pads, the 3 Step Wet Diamond Polishing Pad eliminates the need for four additional steps, resulting in a significant improvement in grinding efficiency. This not only saves valuable time but also optimizes productivity, making it a preferred choice among professionals and DIY enthusiasts.

Crafted using the finest quality diamond particles embedded in a resilient resin matrix, these polishing pads offer exceptional cutting and polishing performance. The high-density diamond particles ensure a smooth and flawless finish, leaving the surface with a brilliant shine that enhances the natural beauty of the stone.

The advantage of the 3 Step Wet Diamond Polishing Pad lies in its compatibility with water as a lubricant. When used with water, this pad acts as a coolant, reducing friction and preventing overheating. This ensures a prolonged lifespan of the pad itself while also maintaining the integrity of the surface being polished.

Furthermore, the wet polishing method employed by this pad significantly improves the overall working environment. By minimizing dust and debris, the process creates a cleaner and safer workspace. Additionally, the use of water facilitates better polishing results by enhancing the effectiveness of the diamond particles, resulting in a higher level of precision and quality in the final finish.

1.Good sharpness with long lifespan, fast polishing with high glossiness.

2.Using high quality raw material ensures both good sharpness and long lifespan.

3.Saves four steps which greatly improves the grinding efficiency.

4.Other grits and sizes are available as requested.

5.Competitive price and superior quality.

6.Supply the whole set of grinding and polishing tools from rough grinding to fine polishing.

7.Support OEM and ODM service. Special specification can be available upon requirement.

|

Type |

Diamond polishing pad |

|

Application |

For granite, marble and other stone surfaces grinding and polishing |

|

Size |

3’’(80mm), 4’’(100mm), 5’’(125mm), 6’’(150mm) |

|

Grit |

50#100#200#400#800#1500#3000# |

|

Special specifications are available upon to customer’s requirement |

|

Why choosing GUANSHENG brand products:

1. Professional technical support and solution;

2. High quality products and reasonable price;

3. Various of products;

4. Support OEM & ODM;

5. Best customers service